Earlier this month, we were invited by OPPO Philippines to visit their factory and HQ in Shenzhen, China. Having seen the assembly process of Cherry Mobile’s Flare X last year, I already had an idea what I’ll be seeing in OPPO Factory Tour which I’m sure is on a larger scale. Also, OPPO has been praising about their phones’ quality so I expected to see their during the trip.

OPPO FACTORY TOUR

The travel time from our hotel to OPPO’s factory took around an hour. We already knew we’ve reached our destination upon seeing the OPPO logos pasted outside the facility. A big facility. We’re only going to visit only one building though, where their manufacturing department is located.

We were briefed of what we’re going to see and learn inside the factory. Before we entered, we were all asked to wear a cap, a lab robe, and disposable shoe covers. Why do we need to wear these? Like in any other laboratories, it is simply to prevent contamination. There’s even an air shower to blow off dust and other particles before entering the SMT lab. The translator provided us with earpieces so we can hear her voice inside the noisy environment.

SMT CENTRE

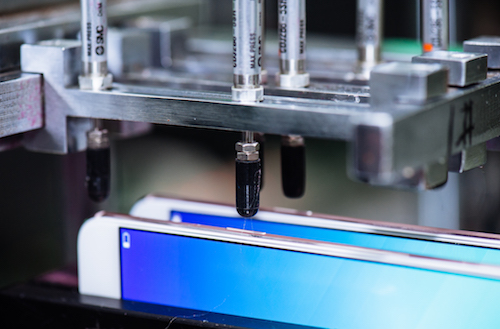

The first area we entered was the SMT Center. SMT or Surface Mount Technology is a method for constructing electronic circuits in which the components are placed directly onto the surface of printed circuit boards or PCBs.

The process starts with the manufacturing of motherboards. OPPO ensures the quality of the motherboards by making 3 key efforts in the SMT Center.

- Every SMT equipment is from best-in-class manufacturers in the world.

- 18 Quality Inspection processes to ensure all motherboards delivered to the assembly workshop are of best quality.

- The Quality Standard OPPO has set for the SMT Center is probably the highest in the mobile phone industry and far beyond the national standards in China.

Components are added to the motherboard step by step. After each component is added, there is another machine to verify whether the products produced by the previous machine are qualified or not. In the video below, you will see that most of the inspections were done by machines and only one inspection process was done manually.

Here is a video of my visit to the SMT Center to give you an idea what it looks like inside and how their process work:

According to OPPO, there are 38 motherboard production lines and 25 small plate production lines. The production capacity of each month is 7.5 million motherboards/25 million sub-boards.

ASSEMBLY LINE WORKSHOP

Unfortunately, we were not allowed to take photos and videos inside the Assembly line. The photos you see here were supplied by OPPO. In the assembly line, internal parts like camera modules and LCDs to externals like the front and back covers are put together.

QE LAB

Once the phones are already assembled, around 12% of them are brought to the QE Lab for various tests. These tests involve electrical performance, structural, and environmental aging. Here are some examples of the tests that were regularly done on the phones to ensure the quality you get when you buy an OPPO Camera Phone:

Micro Drop Test The front and back of the phone is dropped at a height of 7 cm. for 20,000 times each side.

The front and back of the phone is dropped at a height of 7 cm. for 20,000 times each side.

Drop Test

The phone gets dropped for at least 1 meter. If the first drop test is successful, the second drop test will be done but raised to 1.5 meters.

Button Click Test

Volume buttons are prone to wear and tear due to its movable parts. OPPO taps each key 100,000 times with the force of 1kg. The fingerprint key gets tapped 1 million times.

Tumble Test

The phone is placed inside the blue container and gets rotated 75 times. They expect for the phone to have cosmetic damages but if any of the phone’s functions fail, then the test fails.

Rain Test

OPPO phones don’t really have waterproof features, but they do some rainfall tests where they check if there was any corrosion on the main board and screen.

Overall, I am impressed with the processes I’ve seen during the OPPO Factory Tour and it reinforced my belief that OPPO indeed produces high quality phones. So if you have friends who doubt about these phones’ quality, share this article to them and most probably they will be convinced to buy an OPPO phone too.

* Special thanks to OPPO Philippines for flying us to Shenzhen, China for our OPPO Factory Tour.